Castable Resin Material for 3D Printing for Jewelry | TIKO-G

€99.00*

Available, delivery time: 1-3 days

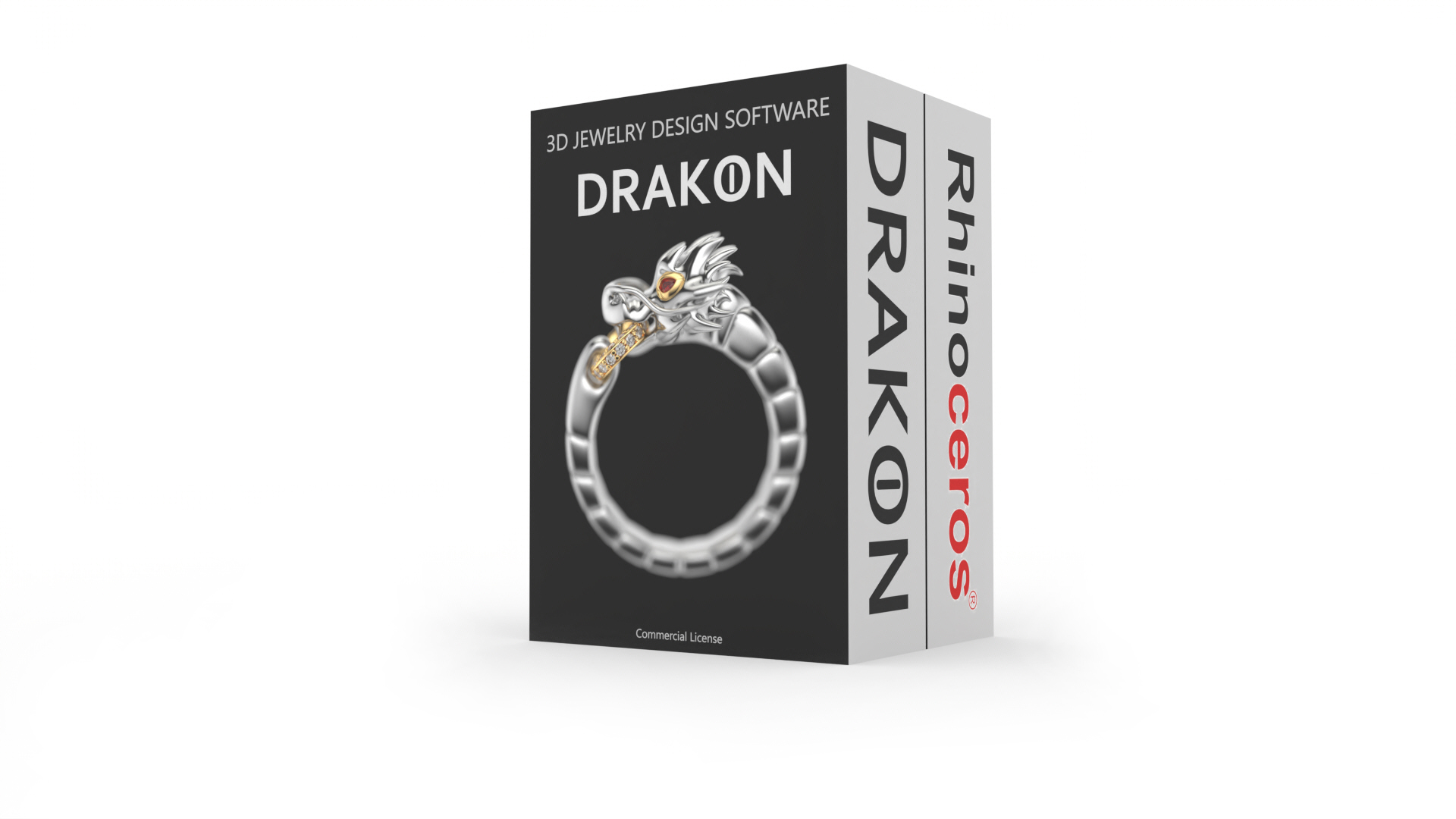

Product information "Castable Resin Material for 3D Printing for Jewelry | TIKO-G"

| Color: | red |

|---|---|

| Content: | 0.5kg / 1 kg |

100% ash-free combustion from 700 degrees

100% dimensionally stable after printing

For all DLP, SLA and LCD printers

Made from 20% + sustainable raw materials

Castable resin for innovative goldsmiths

_FREI.jpg)

_FREI.jpg)

_FREI.jpg)

Castable Resin Burnout - Sequence of the lost wax casting process

The lost wax process is a molding process for glass and metal casting. Usually, one-piece molds are made of wax. In the course of the process, not only the model but also the mold is destroyed. In the lost wax process, the model is provided with both sprue and vent channels.

1. Preparation

Preparation of molding material and coating with molding material/investment material, which leads to the formation of green mold.

2. Melting out the green mold

Melting out the green mold creates a mold cavity, which is dried in the case of water-containing molding materials. For plaster models, partial vacuum drying is required beforehand.

3. Melting process

Depending on the investment material, firing of the mold takes place. The molten glass or metal is poured into the respective mold. The molten mass solidifies in the mold. Now the mold is smashed so that the raw casting can be removed.

Customer reviews of TIKO-G

Thank you!!

We were allowed to test the new resin with as first. Thanks again to the Mack4D team. :-)

Marise de G.

Compatible with our DLP.

Everything as expected!

Jens M.

Finally!

I'm really glad that now also times our industry of goldsmiths wakes up and becomes sustainable. 20% sustainable raw materials in TIKO-G are a good start in the right direction.

Julia K.

It works!

Was skeptical at first... but integrates well with our customer process. Burns after triple testing always completely

Rudolph K.

Castable Resin TIKO-G supports popular 3D printers

TIKO-G Castable Resin is the first jewelry casting resin made from more than 25 percent renewable raw materials. In addition to its sustainability, TIKO-G Castable Resin scores with its outstanding product properties. The material is absolutely dimensionally stable after printing, so you can embed the printed model immediately. In addition, TIKO-G Castable Resin is compatible with most 3D printers.

- Advantages

- Suitable for all models created in the investment casting process. Can be burned out.

- No expansion occurs during burnout.

- Low ash content during the burnout process.

- Sublimation starts at 130 degrees Celsius.

- Compatible with many gypsum-bonded investments.

- Very high detail accuracy.

- Excellent casting of small engravings (both positive and negative).

- Perfect, smooth surfaces.

- Cleaning with commercial spirit.

TIKO-G for DLP Printers

TIKO-G's burn-out, castable resin is monomer-based and excellent for LCD as well as DLP 3D printers. Both handling and post-processing are very easy. TIKO-G is suitable for all models produced by investment casting. The castable resin is used in jewelry and dental models. Using CAD programs, dentists, jewelers and designers can design their objects digitally and produce them immediately afterwards - in maximum resolution (depending on the printer).

Our Castable Resin for SLA Printer

Our Castable Resin is a castable resin for use with SLA and DLP 3D printers. You can use the TIKO-G for all investment cast models. Classic applications include jewelry and dental models. After jewelers and dentists as well as designers have created their designs using CAD programs, they can immediately turn the respective designs into reality. TIKO-G allows you to cast optimally with common wax equipment and plaster-bonded investment materials. The photopolymer, which is filled with up to 80 percent wax, not only burns out cleanly, but without any ash content. The castable resin captures very complex details and allows for very smooth surfaces. This results in high-strength jewelry pieces that require large amounts of metal. The high accuracy of the details allows excellent reproduction of lettering, pavé settings or very thin lines. Even at lower temperatures of 750 degrees Celsius, full burnout is guaranteed, which is the best solution for stone presetting.

Jewelry Resin for LCD Printer

TIKO-G's castable resin adopts in both LCD and DLP 3D printers. It is used in highly detailed models of all types of investment casting processes. Dentists and jewelers in particular swear by castable resin because they can easily design their objects using CAD programs and then immediately create an investment casting mold. Especially for the realization of complicated models with high dimensional accuracy, TIKO-G is the ideal solution. It enables perfect casting quality with any investment material.

Frequently asked questions about TIKO-G Castable Resin

- All jewelry models

- Jewelry with intricate details, thin walls, pavé settings and fine surface details

- Larger castable parts

- Prototype fabrication

- Jewelry customization

Length x width x height x density

You can take the exact density from the product data sheet, whereby the guideline value is about 1.2 g/cm³.

Frequently asked questions about TIKO-G Castable Resin

Who is Castable Resin suitable for?

TIKO-G Castable Resin allows you to create high quality jewelry creations without much effort through flexible burnout and casting processes. From sophisticated bridal accessories to intricate designer jewelry, Castable Resin can be used to print highly detailed jewelry pieces. Low expansion, compatibility with industry-leading investment materials and residue-free burnout make TIKO-G Castable Resin particularly attractive to jewelers. The casting process and short curing time without post-curing also speeds up and simplifies the workflow. This makes TIKO-G Castable Resin the ideal material for your jewelry business. Whether you are a beginner or advanced, a mass producer or a craftsman, TIKO-G Castable Resin makes the production of 3D printed jewelry easier and more efficient.

How do goldsmiths use resin?

With powerful equipment and materials, designers and manufacturers are saving time traditionally spent manually preparing jewelry. With cost-effective, intuitive desktop 3D printing capabilities like the Formlabs Form 2, high-quality 3D printing is becoming increasingly affordable and scalable for jewelers. Highly detailed jewelry is known to require painstaking and time-consuming manual labor. But in our fast-paced world of high demand and short-lived trends, jewelry made by hand can usually struggle to keep up. The development of castable resin now enables first-class manufacturing on affordable 3D printers. It combines exceptionally high strength with a smooth surface finish. The precise print settings capture even the smallest detail. Subtleties such as filigree wires, meshes or pavé settings are highlighted and precisely captured. Castable resin with a wax content of over 25 percent enables very clean casting and reliable burnout. It is suitable for standard burnout schedules on the one hand and for shortened eight-hour burnout schedules on the other. The resins developed by TIKO-G for investment casting and jewelry making reproduce fine detail and and allow for custom jewelry pieces at an affordable price. Castable resin is therefore more in demand than ever throughout the manufacturing process for goldsmiths, jewelry designers and jewelers.

At what temperature does the resin melt?

Castable resin does not melt. Instead, sublimation begins at 130 degrees Celsius. Sublimation is the term used to describe the transition process of a solid material into the gas phase. The recommended burnout schedule is designed to allow Castable Resin to slowly transition to the gaseous state. The gradual sublimation prevents the rapid expansion of the printed part so that no cracks form in the investment material.

What is castable resin used for?

Castable resin is used for casting filigree jewelry, among other things. Both detailed and voluminous models can be easily printed with Castable Resin. The simplified and accelerated burnout and direct investment casting process without post-curing allows you to finish with only minimal effort. Castable Resin printed parts are strong enough and suitable for both prototyping and fitting before actual production. You can use TIKO-G Castable Resin for the following:

- All jewelry models

- Jewelry with intricate details, thin walls, pavé settings and fine surface details

- Larger castable parts

- Prototype production

- Jewelry customization

How much Castable Resin do you need?

To determine the amount of Castable Resin you need, you can use the following formula as a guide:

Length x width x height x density

The exact density can be found in the product data sheet, whereby the guide value is about 1.2 g/cm³.

| Color: | red |

|---|---|

| Content: | 0,5 kg |

Login